Updated 2023-04-22

Introduction

This is an open source Arduino based CW (Morse Code) keyer with a lot of features and flexibility, rivaling commercial keyers which often cost significantly more. The code can be used with a full blown Arduino board or an AVR microcontroller chip can be programmed and used directly in a circuit. This keyer is suitable as a standalone keyer or for use permanently installed inside a rig, especially homebrew QRP rigs. It’s open source code so you can fully customize it to fit your needs and also perhaps learn from it or find coding ideas for other projects. A circuit board and parts kits called the nanoKeyer is available from DJ0MY, Hamshop offers a kit called Open CW Keyer , RemoteQTH offers the Open Interface . The Mortty and the YCCC SO2R Mini also run this software. Please do not directly email the software author for support. Consult this page for code support information.

Various tutorials, demonstrations, and development news updates can be found on the Radio Artisan YouTube channel and numerous implementation demonstrations and how-to videos are on The YouTube.

Main Features

- CW speed adjustable from 1 to 999 WPM

- Up to six selectable transmitter keying lines

- Programming and interfacing via USB port

- USB or PS2 Keyboard Interface for CW keyboard operation without a computer

- Logging and Contest Program Interfacing via K1EL Winkey 1.0 and 2.0 interface protocol emulation

- Command Line Interface

- Optional PTT outputs with configurable lead, tail, and hang times

- Optional LCD Display (Classic 4 bit LCDs and I2C displays supported)

- Up to 12 memories with macros

- Serial numbers

- CW keyboard (via a terminal server program like Putty or the Arduino Serial program, or a USB / PS2 keyboard)

- Speed potentiometer (optional – speed also adjustable with commands)

- QRSS and HSCW

- Beacon / Fox mode

- Iambic A and B

- Straight key support

- Single Paddle

- Ultimatic mode

- Bug mode

- CMOS Super Keyer Iambic B Timing

- Paddle reverse

- Hellschreiber mode (keyboard sending, memory macro, beacon)

- Farnsworth Timing

- Adjustable frequency sidetone

- Sidetone disable / sidetone high/low output for keying outboard audio oscillator

- Command mode for using the paddle to change settings, program memories, etc.

- Keying Compensation

- Dah to Dit Ratio adjustment

- Weighting

- Memory stacking

- “Dead Operator Watchdog”

- Autospace

- Wordspace Adjustment

- Pre-configured and Custom Prosigns

- Non-volatile storage of most settings

- Modular code design allowing selection of features and easy code modification

- Non-English Character Support

- CW Receive Decoder

- Rotary Encoder Speed Control

- Sleep Mode

- USB Mouse Support

- QLF / “Messy” Straight Key Emulation

- USB Keyboard HID (Human Interface Device) Interface (Keyer = keyboard for your computer)

- Keypad Support

- Web Interface

- Linking of keyers over an IP network

- Mill Mode

- TX/RX Sequencer

- Training Module and Various Practice Modes

- American Morse Mode

Some videos featuring the keyer:

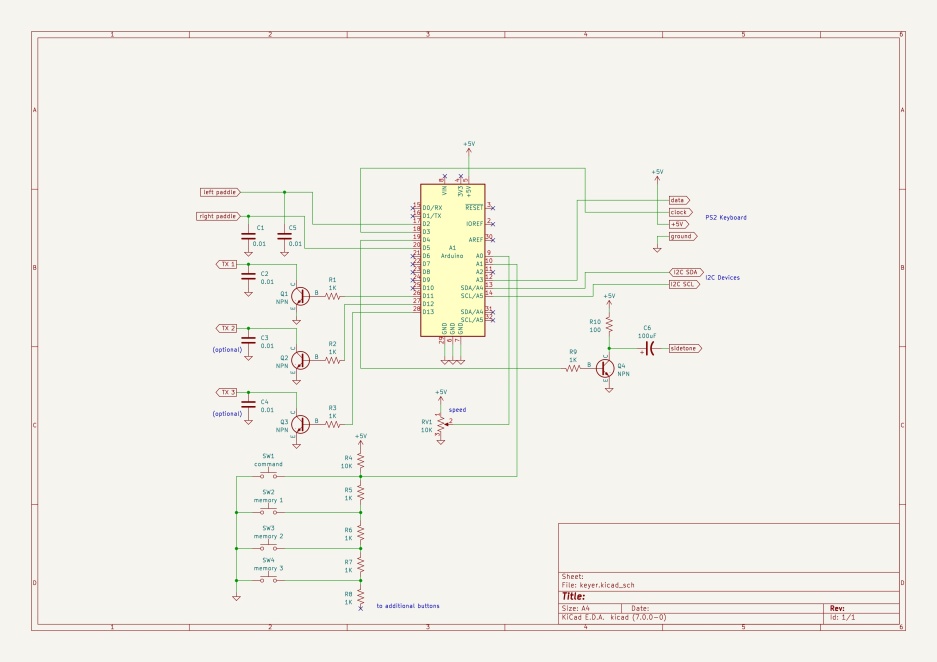

Basic Schematic

A Fritzing breadboard plan of the keyer

KF4BZT Article – Good information for new builders!

DL1SMF Keyer Project (English Deutsch)- Stefan has details on his hardware which is pin compatible with this software and his own software.

Jeff, AC0C, wrote of his efforts to find a CW keyer with an “Old School Feel”.

Barry, ZS2EZ, published a web page on his K3NG CW Keyer build, including a schematic and PC board artwork.

Documentation

Authoritative documentation is located in the Github Wiki.

Numerous helpful videos can be found on YouTube.

The Code

Source code is located on GitHub . Click the Download Zip button on the lower right to get all the code in a ZIP file.)

Older code versions can be found here. Click the commit you’re interested in, click Browse Files and you will find a Download ZIP button that you can use to download that particular git commit / version.

In order to accomodate the growth in interest, support for all my projects and all discussions have been moved to this Yahoo Group: http://groups.yahoo.com/group/radioartisan/ . The comments areas on the blog are now disabled. Thanks everyone for your support. 73 Goody

EDIT 2020: The official support group is no longer on YahooGroups, it’s here: https://groups.io/g/radioartisan

Hello all

Just completed a nanokeyer but can’t seem to download the “Firmware Upload Guide”.

Any known issues or suggestions for an alternate source?

Hi Robin. Where are you attempting to download it from? Upgrading the firmware isn’t too difficult, it’s the same way you would upload a new sketch to an Arduino. You have to select the appropriate features and options in the source code, per the instructions on this page.

Oh I am trying to download from k3ng nanometer.WordPress.com/downloads

Robin

Try this link: http://nanokeyer.files.wordpress.com/2012/01/nanokeyer-firmware-upload-guide.pdf

Excellent! Can’t wait to try it out..

73, Chris

Can you put the source in a zip file. I can’t copy/paste the source correctly.

Thanks!

This is AWESOME!. Many thanks for sharing! I never knew how much you can pack into this little Arduino!

I copied the code and it works perfect.

vy 73 de Hermann AJ4ZS / DL8MCP

Great project. Looking forward for the first experimental Winkeyer emulation mode :-) 73 de DJ0MY

At last !

Any useful ham application for Ham Radio for the Arduino. Been doing some tries myself but your code rock… Great job… Also looking fwd to the Winkeyer “mode”.. Have a Winkeyer thru my microHam today but I like to run things remote some times.

Keep up the good work

73’s de Mats

If I were to run this as a USB-only keyboard keyer – apart from not connecting all the other paddles and paraphernalia – you wouldn’t see any problems running this just as a cut-down keyboard only device?

You can’t connect just a keyboard to it (you still need a computer with a terminal program connecting to the COM port), but yes, it will function fine without a paddle as all the commands needed to control it are available in the command line interface.

If you’re looking to just connect up a keyboard directly to the Arduino (computer), I can probably have that functionality in the code in pretty short order. Let me know if that’s what you’re looking for and work something up :-)

73

Thanks — I thought as much, but wanted to check. And no, I’m not interested in connecting a USB keyboard directly, even if the Uno’s potential for HID is there.

73 de VA3PID

Hi Anthony, is there any progress on the Winkeyer “emulation” – are you still intending to work on it?

Hi Oscar. Unfortunately there is no new progress to report. I’m still going to try to get the emulation working, but I have submitted a feature request to N1MM for functionality to support “generic” external keyers.

Tony —

Just finished assembling my version of your arduino keyer.

It is amazing, thanks for the leads, I’ve made a few changes that better suit my needs, not sure

if they are improvements as much as tailoring… like a custom suit of clothes. Still it all came

from your base, thanks. I’ll send you my minimal changes as well as photos of completed unit

once it is mounted.

Thanks again!

73,

Art

K0ACP

Hi Art. Good deal! Please do send me your customizations. If you see a need for them, undoubtedly someone else will as well and I may be able to incorporate them in as options. That’s the great thing about define statements and modular code; you can add and remove options easily at compile time.

Thanks for dropping me a note. I like it when people can benefit from the code!! :-)

73

Goody

K3NG

Art,

I would like to see how you mounted yours. Looking for ideas for mine too.

73,

Chris k4fh

Please take a look at the K1EL “OpenQRP” project. Steve has created a complete 40M transceiver using an Arduino CPU with all his famous K1EL WinUSB keyer features and system control functions.

http://www.openqrp.org

thanks,

dit dit

72/73 de Ken N9VV

CFO #287

Hi Ken. When you mentioned the OpenQRP project to me back in March I joined the site and also offered to volunteer some coding time to the project. No one has taken me up on my offer, but my offer still stands. It looks like a good project.

I should mention that it’s not my goal here to compete with the Winkey or any other keyer project. I just like the Arduino and coding, and I wanted to implement my PIC keyer on the Arduino platform. The project took on a life of its own and it does much more than my PIC keyer project did. Admittedly I think I’ve become addicted to the Arduino.

73

Goody

K3NG

Hi Ken and Goody,

from what I can read on his site K1EL has so far only implemented his keyer code (from his stand alone keyers like the K12) into the QRP-Radio firmware…not the Winkeyer.

The reason is simply because his current QRP hardware does not forsee a RS232 serial port or USB port for external connection to computers (would be a nice addon, though).

73 Oscar

I’ve got this bread boarded. Have you laid out a PCB yet?

73,

Chris k4fh

I’ve been too busy coding software to lay out any hardware :-) Since the Winkey interface emulation is pretty much done, I’m going to focus on the PS2 keyboard feature for a bit and after that I think I’ll design a keyer shield.

Goody and team,

I used ugly construction on a proto-shield for my effort and plugged that into a Arduino Uno board, when I get sometime, I may try a custom layout from PCB express.

I did order a box from Mouser p/n: 546-1455N1602BK Hammond Enclosures, Boxes, & Cases 6.3 x 4.06 x 2.09 This is an aluminum box with plastic end pieces and works very well.

Since I only have a single rig, I only connected up a single transceiver line. Also, later I’ll either post a link to the mouser bom or paste a copy of it here.

Wow the keyer works great!

Goody, thanks for putting this out there.

783,

Art

K0ACP

Can you post some pics when you get it cut? Some people fret over the circuit and what is inside. I’m one of those that will use ugly, dead bug, etc and not care but fret for hours over the perfect enclosure. I’m planning on building two of these for 2 CW stations for use at a special event in October. http://www.qrz.com/db/k4l

73,

Chris k4fh

WOW!!!

Awsome work you have done!

TNX es 73 de SM0RVV

Thanks all for your kind words :-)

This weekend I have another update coming out. The Winkey interface emulation is now 99% complete and I’m making major updates to the PS2 keyboard feature would should get it to the 95% completion level with CTRL key combinations to set most parameters and memory programming. Also with this update the number of memories can be easily changed at compile time and the PS2 keyboard will support up to 12 memories and the CLI will support 9. If anyone wants more memories supported with the buttons, let me know and I’ll work on a button MUXing scheme. I’m also going to find a way to support more transmitter lines and have it easier to configure at compile time. I want to be able to switch between multiple rigs in the shack without swapping cables.

After this update I think I may work on the I2C and LCD display functionality I’ve been thinking about.

73

Goody

Okay, is there enough room for all those enhancements :) I enabled the the practice feature last night and the IDE had an issue uploading. After sending some of the stuff it complained that the UNO had stopped responding. I think the compiled code was about 30k. Probably just an issue on my Ubuntu machine.

I’ll have to merge your updates with some of my minor changes. In lieu of the practice feature you may want to add a command that will set key_tx = 0. This will allow folks to use the keyer as a practice oscillator. I guess the non-lazy person could just unplug the tx cable from their radio instead :). The result would be the same.

On the muxing you could use one analog port and then use resistors. You could also use a 4051 multiplexor. I thought about changing the code to get more memories by adding buttons but the reality is that my case is going to be packed if I any more! At home I use a serial interface I built and CWType. In the field I use AA0ZZ. The AA0ZZ has 3 memories and I’ve never ran into an issue where that had not been enough. It is still good you are thinking of it so for others who want 20 buttons on a case they can have those.

I’ve been enjoying playing with this thing and it is consuming much of my time.

If you are using agle Cad and would like to share the file for the version that is on this page I would be interested in laying out a PCB for it.

73,

Chris k4fh

Darn. I think I’ve been playing with the 07/18 code. There are many differences between what is above and what I have.

New code posted. Note that the modified PS2Keyboard library files are posted here now, instead of just the code modifications. The modifications to add support for CTRL key combinations were getting too extensive to just list the changes.

I’ve not plugged in my power supply in the UNO so this may be relieved. Everytime in Linux the port is opened it resets the Arduino. I’ve got WINKEYER mode set to default and I had to not say HI when using CWType. Could be related to timing and WINE but if it did say HI CWType would error that there was no response.

I’ve almost got my enclosure complete and it looks good. I only had room for 5 buttons. Paid $2 for the case at a hamfest. Plastic so I hope this does not cause issues with lack of shielding. So far I’m able to TX at 20w in my shack.

Chris

Hi Goody,

I have not found the updated PS2Keyboard Libraries on your site.

Looking forward to trying this version out. I still had issues with the last version and spacing in CW (very very long delay between words with the keyboard).

Cheers,

The modified .h and .cpp files are above, right below the main code….

How could I’ve miss that !? Tnx, 73

Updated code and schematic posted. Multi-transmitter capability is now implemented using multiple PTT lines rather than multiple TX key lines, and the PTT line (now PTT line for transmitter 1) moved to pin 13.

I’m currently working on button multiplexing using an analog pin and voltage divider resistors in order to free up pins for the upcoming LCD display functionality. This will also allow the number of buttons to increase. I’m thinking of up to 19 buttons total (one command button, 12 memory buttons, 6 LCD soft keys). The number of buttons would be optional, as would the LCD display functionality.

Thanks to Oscar and Chris for ongoing bug reports and code improvement ideas. :-)

I am seeing some issues with character sending on both paddle input and keyboard. I see that the cw speed starts out slow and speeds up slightly but noticeable, +2, 3 wpm. I am not sure what’s going on. Do others see this symptom? I’ll upload the new code later this weekend and see if it makes any differences.

On another note, the issue with the “space” timing being so long (previous note able) was a result of the ATMEL chip being bad. I replaced the processor and the space timing issue went away.

Also, I’ve added a simple serial LCD display to prior to the latest code. Seemed to work ok, just needed some additional formatting/scroll code. (By the way, I am using unmodified code during my testing with the timing issues stated above.)

73, Chris

Hi Chris,

I had a similar problem with changing code speed. In my case it was related to a missing speedpot.

I compiled the speedpot part although I had no speeedpot on my breadboard.

After removing the speedpot option and re-compiling everything was fine.

The latest keyer code works mostly fine here (but I do not use the keyboard – only winkeyer mode and paddles).

73, Oscar

Oscar, that makes total sense…. Thanks for the reply!

Cheers,

Chris

Updated code posted. This code introduces analog line multiplexed buttons, so now up to 16 buttons (maybe more) are supported. This is to free up some pins for the upcoming LCD functionality and also provide more buttons for LCD display “soft keys”. Memory repeat can now be done without a memory macros (CLI: \! , PS2 Keyboard: ALT-Fx , or button hold + left paddle).

If you want to continue to use the old buttons (one button per pin) uncomment #define FEATURE_LEGACY_BUTTONS . I don’t know how long I’ll continue to keep the old code in there.

Wow, where are you finding the program space on the chip? Have you upgraded?

I have purchased about $50 worth of goodies from Evil Mad Scientist. I’m going to build one out on one of their proto PCBs and then put it in an enclosure. I use CWType with winkey support but after reading a Winkey vs cwdaemon email on QRP-L I’m debating about modifying the circuit to support RTS keying. This would make the AVR chip functionally worthless but I’m thinking more on the lines of the RTS in the circuit being an option and not standard. The RTS line would key TX1. Of course it could be used on a digital input pin and then the AVR could key. Like a pass thru.

Chris

I can’t fit everything into an Uno. However, I suspect most folks won’t want or need all features in one box. I still haven’t gotten a Mega, but now that I’ve freed up a bunch of pins for the LCD I’ll probably hold off a bit. But it will be cool to compile the whole nine yards sometime and upload it to a Mega…

Mouser is having an on line sale of the Arduino Mega board. $46.55 Not a bad price.

I have running a Arduino Mega Icom CI-V router / USB Interface / band decoder that cures problems for those who are running the ICOM PW-1 and a XCVR with a computer interface. Contact K9JM for Info

Just got the keyer built as a simple USB serial TTY-to-CW unit. With careful wiring (and brute force and ignorance) I fit a speed control pot, two buttons and a simple piezo as a sounder into the standard Arduino project box – https://www.sparkfun.com/products/10088 – with the wiring on a protoshield. Worked first time! Made a nice QSO with an operator in TN with Fldigi decoding his CW. Thanks!

(Also: as an avid Hellschreiber user, we *have* to do something about that font you used …)

73 de VA3PID

This little section of the documentation is very important –

Code Compilation

All of the features will not fit on an Arduino Uno simultaneously. I find that when the compiled code goes over about 29K, the upload to the Uno will fail.

Ran into this with a code size of 29004K and the error message is not very helpful…

Changed my options and it works great.

I must be lucky; I got 29962 bytes to work on my Duemilanove.

I was told by someone that the Uno bootloader has a bug that causes it be unable to receive a software load that’s larger that 28K or 29K, and there is a hacked/fixed bootloader that you can write onto your Uno to upload these larger loads. I have not researched this, your mileage may vary.

There is a bug. If you have an ISP programmer you can program a new version of optiboot that fixes this bug.

Ah, yes, it was Chris who told me. Thanks, Chris. One of these days I have to download that and try it.

Anthony,

I am almost done with my own build using the EvilMad Scientist boards and Hammond enclosure. I think I’ve found a bug in your schematic. I’m using the July schematic and code. In Winkeyer mode when I use a paddle it seems to behave erratically. It works when I key but seems to lock up or shut down. I’ve added 1K resistors on D2 and D5 and this seems to fix the problem. I’m going to close the box up and try it out during a QSO. This is all new to me so I’m not sure what may be going on but I have an idea that too much current is being pulled and the low voltage protection that I’ve enabled in the fuses is kicking in and the chip is shutting down. You may want to modify the new schematic.

73,

Chris k4fh

Are you powering this via USB or the coaxial jack? Does this occur when connected to a rig or just when using it “dry”? The D2 and D5 lines shouldn’t be able to load down the power supply as they’re just being pulled up with internal pullup resistors, probably on the order of 1K or more. Do you indeed see the V+ line getting loaded down with a voltmeter?

I am powering via a DC coaxial check using power off the USB bus. What I have seen a voltage drop after this occurs. So far with the 1Ks I can’t seem to recreate this. I will also try with a straight key. I could also have a chip issue since this is one I built from the ground up. I can easily order another chip and program it.

I have a question for all the users.

What mode are you using your keyer in when operating on the PC? Currently I’ve programmed mine for WinKey. I have 2 computer keyers. I have a homebrew that uses DTR/RTS. Standard circuit. I have this one that I’ve programmed to do WinKey. I run Linux and use CWType. It can use either keyer. I’m curious if anyone is using the CLI method on their computer. I used it as I was experimenting with this and made a QSO, but my terminal program sends and erads in raw mode so it was cumbersome to use this way. I suppose if I modify my terminal program to send in line mode the keyer would not confuse me so much.

I even debated about interfacing the RTS or DTR method with a digital pin so that if that method was required, for a program that did not support WinKey, it could be used.

Just looking for usage comments.

73,

Chris k4fh

I will add a feature tonight to toggle the CLI CW sending behavior between the current way (send characters immediately) and “wait for a carriage return” mode. It shouldn’t be too hard to do as I already have pause sending capability in the send buffer code.

Is should probably send pic of my enclosed keyer

Right to left:

DC 5V

TTL

TX1

Paddle

The blue tack is holding the light pipe in place on the front.

This has no buttons. I built this to be a computer keyer only. It does have paddle input so you could use as stand-alone but you would have no way via the paddle to program the memories. There is no side tone since all my rigs have a ST. but you could not get audio feedback from command mode if you were to somehow invoke it.

I wanted to put a MAX232 on the PCB but there were not enough holes. I have plenty of USB PL2303 to TTL cables so I decide to use TTL as the interface to the device. Since I’m not using a boot loader I have no issues loading the whole code.

I may add male headers that will allow me to use a jumper to go from CLI to WinKey. This would require a code modification and you would have to open up the Hammond enclosure to change modes.

I spent more money and time than if I would have just bought a MasterKeyer but the ROI was education. I can quickly build specific keyers based on the code. In smaller enclosures.

Chris

Chris, try this code: https://radioartisan.wordpress.com/k3ng-arduino-cw-keyer-code-in-testing/

This adds a new CLI command \^ which toggles “wait for a carriage return to send CW”.

Well, while we’re sharing pictures:

http://scruss.com/blog/2011/09/24/k3ng-keyer-complete/

I may need to add a way of accessing the reset button, as from boot, neither my Linux box or Mac can create a TTY (= serial port) for the device.

One weird thing is that the Memory #1 button seems to randomly cycle between any of the programmed memories. Dunno if it’s how I’ve wired it. The Command button mode works fine, if a little bouncy.

Cheers for this design. Using fldigi to copy the incoming code, I’ve made several DX QSOs.

73 de VA3PID

The reset problem was because I was using a Duemilanove. When I swapped in an Uno, all has been sweetness and light.

Hi Anthony, I’ve had two reports that my Hellschreiber output is illegible using your keyer. Both were used mid-QSO with experienced Hellschreiber operators. I thought at first it was the capacitor in the keyer circuit, but replacing that with a tiny ceramic made no difference. I’d be happy to help out testing, ‘cos I’ve intrigued several people with the idea of a Hellschreiber keyer.

How are you keying the transmitter? Are you using the sidetone output going into the audio input of the rig (in SSB mode) or using the CW key line with the transmitter in CW mode? I could see where the squarewave output might not play well. Did the people who provided the reception reports take a screen shot of what the received signal looked like?

I’m using the CW key line with the transmitter in CW mode. I got no screen shots from the contacts, but descriptions like slanted, smeared, timing off, and illegible. I had to switch back to Fldigi’s SSB Hellschreiber mode to maintain a conversation. I’ll try a screen shot request next time; there’s a QRO operator in Louisiana with whom I’ve traded screenshots before, and I can ask again.

Sounds like a timing issue. I had to play with the timing a bit to get it to display correctly for me. For some reason the original values I calculated for the code didn’t work. I’m not sure why.

If you fire up your Hell program and use your computer microphone to copy the hellschreiber from the keyer sidetone output, you should be able to see what it looks like and adjust the timing. Change the number in this line in the transmit_hell_pixel function:

delayMicroseconds(4025);

Why does WinKey need to do EEPROM writes. I saw a feature to disable that and mine is still disabled. At K4L I ran into an issue where N1MM would not work with ESM on my keyer. With ESM turned on you simply hit enter to send the macros. If you hit F1 to do CQ and get no returns you simply hit ENTER again. On my keyer I had to hit F1. We then installed the K1EL keyer and it worked fine. I’m thinking this has something to do with that feature, but I’m also wondering why it is even required and why it is so darn complicated. Why can’t N1MM simply send macros instead of putting the keyer in some form of state. I am back from St. George Island and need to do some more testing. I’m new at N1MM and do not use it regularly.

Chris

Winkey changes some settings that are non-volatile settings, most notably the CW speed. By default the code doesn’t write to EEPROM, but if you enable strict writes it does. I’m not sure why anyone would want to do this, but the option is there. N1MM does a setup routine after initially connecting to the Winkey and each time you send a memory or activate the CW keyboard it sets a few parameters. So there isn’t really much of a need to store any settings when using Winkey.

I’m not sure why N1MM ESM wouldn’t work. I would expect it does the same commands it does for memory sending and CW keyboard (CTRL-K). Can you get a capture of the serial port when doing N1MM ESM?

In ESM mode you would hit F1 or enter to send CQ. This worked. What was strange was that after no caller hitting enter would no send CQ. I need to keep doing some testing.

Anyone using CQRLog with this? I’m having some issues getting it to see it.

Do you have ASR (automatic software reset) disabled? I had problems with HRD and ASR activated. Does the keyer send random / errant characters upon connection? That tends to point to ASR screwing things up.

I do not as far as I know. I’m “in the raw”. I’m not using UNO. Just the ATMega328 with API. I need to do more testing.

Hi folks,

I could replicate Chri’s problem, when ASR is enabled (= default Arduino config)

I noticed that the keyer code would not send back a version number to N1MM during initialization and each macro (no matter if sent via the PC function keys or via ESM mode hitting return) is not terminated by a C0 status byte and therefore N1MM hangs because it is waiting for the transmission to end forever….

As Goody ponted out you need to disable ASR, otherwiese the serial port communication is creating trouble…

I tested ESM mode (with ASR disabled on the Arduino) with N1MM and it works perfectly well with the latest keyer sketch version….

One easy way to disable the hardware based ASR (automatic software reset) is to put a 100-200uF electrolytic cap between the Reset and GND pins. This keeps the voltage up and doesn’t allow the serial port anymore to pull the line briefly down to reset the microcontroller. This way you do not need to cut PCB traces… ;-)

This mod is also essential for using the keyer with other software such as HRD, etc.

Only drawback of disabeling ASR is that when you upload a new modified sketch to the Arduino you need to reset it manually just within a second or so when the RXD/TXD LEDs start to flicker.

73 de Oscar DJ0MY

Oscar,

I have abandoned using UNO for my keyer. I use the chip, 16mhz rock, caps, and a few other discrete components. My setup does not support ASR. My USB->TTL adapter is only using TX,RX, and GND. There is no way I could reset the keyer when I connect to the port.

ESM works for me but this is what fails.

Hit enter to send F1. This works

Hit enter to send F1 Again. This does not work.

If I replace this keyer with the K1EL WinKeyer USB then the above DOES work. I have not been able tro track down what is causing this behavior. This keyer works fine for CWType. It will not work with CQRLog.

I have an ATmel ISP serial programmer that I use on my build.

This is what I’m using

#define CODE_VERSION “2011080501”

73,

Chris k4fh

Oscar and Chris, when the problem is present, when the program attempts to connect to Winkey, do you hear a “boop beep” from the keyer? That indicates that it received a connect request and it has initiated the connection. If it doesn’t think the connection is up (no boop-beep), it won’t send the version number or C0 bytes. If you’re having connect problems or it is connecting but you’re still experiencing issues, and serial port capture would help me troubleshoot it.

BTW, I posted updated code. There haven’t been major changes, just little items here and there.

I need to modify the code to do the boop_beep via LED. I have no sidetone.

Chris,

my ESM works as it should with the latest sketch (not the one that Goody just uploaded, but the previous revision). I only need to disable ASR….

If I hit enter, the F1 text is triggered (CQ)

I leave the call sign box empty and hit enter again and CQ is triggered again….

This goes on again and again every time I hit enter……….

When I then type a call signt into the call box and hit enter the call + rst is sent….etc.

(just as the ESM mode should be…)

If your homemade board doesn’t support ASR this clearly can’t be the issue…

I would try to re-program with the newest sketch and do some serial port sniffing if the problem persists.

I suggest to use the Freeware Serial Port Monitor and monitor the data streams. This helps Goody a lot with debugging…

http://www.serial-port-monitor.com/

73, Oscar DJ0MY

I was afraid of that. I’ll do some more work. Using the latest sketch may require me to make a few changes to the code. I’ll check and see.

Is there anyone here that is building a keyer “in the raw” using this code? If so, I would like to team up so we can discuss ideas without bothering Anthony. If interested please send me a message.

73,

Chris k4fh

I was able to test N1MM ESM successfully this evening. I haven’t had a serial monitor for awhile as the free trial one I was using ran out of time and disabled itself. So, I fired up a virtual machine running XP and installed the serial port monitor Oscar recommended (unfortunately it won’t run in Windows 7, so I had to get an XP box somehow). Any ESM works fine for me. Looking at the serial port conversation, N1MM sends the same bytes as if you were hitting the keys without ESM.

Perhaps soon I can breadboard a “bare chip” circuit to test that out.

Hi Goody, *PLEASE* *PLEASE* work with Steve K1EL to incorporate your keyer in his new OpenQRP.org kit. I just finished my Beta kit and it is simply a wonderful rig. *BUT* It really needs the WinKey style keying with features and adjustments that you have created. Please contact Steve and work out some schedule for incorporating your amazing new code in his Arduino.

thank you,

72/73 de Ken N9VV

I’ve already been in contact with him; I’m half of the way through building my beta kit and should have it completed this weekend.

Hi there,

just a quick photo of my perfo-board version of the keyer based on Arduino Nano:

http:/www.qrpforum.de/index.php?page=UserGalleryPhoto&photoID=301

This is a “PC-Keyer Only” version to replace my old LPT port keying cable with N1MM winkeyer mode….

I am still waiting for my PCB’s to arrive from China to make a decent keyer, hi hi…

Oscar, DJ0MY

Oscar,

I can not see the photo. I think a login is required on that site.

I’m interested in what you’ve done. Would also like to know where you had your boards made. I laid out a PCB in Eagle CAD, but have not sent them off to be fabricated. I stumbled upon a vendor named ‘Evil Mad Scientist’ that sells proto PCBs for $3/ea. You see an example in the pic I posted of mine. I like their board, but it can get populated fast. On both sides of the chip are areas that you could install an IC. I wanted to install a MAX232 but there was not enough holes. I ended up just using TTL directly. TTL, Serial or USB, it is all the same to me :)

I’ve been thinking about creating a “portable only” version of this keyer. The only issue I can see is that it is not possible to set memories from the paddle. I’ve been thinking about implementing the method the AA0ZZ keyer uses. That keyer goes into a record mode where you have 1s to send a letetr from the paddle. It beeps between those seconds. If you want a space you simply do not send for that byte. To stop recording you hit the command button. Seems to be a good method.

If you want to contact me directly you can look me up on QRZ.com and my email is in my profile.

73,

Chris k4fh

You can set memories using the paddle in command mode with the P command (not command line, but command mode where you hit button 0).

Chris,

I used ITeadstudio from China for the PCBs….I will post some pics after thez have arrived (I just got the shipping notification mail from them)

Try this new photo link:

Nothing spectacular…

On the upper part you can see the electrolytic cap to deactivate ASR mode on the Arduino.

I love the Arduino Nano’s – they are soooo tiny.

Oscar

This is amazing work!

Not being an EE, and having limited building experience, please allow me to post a question or two and expose my noob-ness :) .

I’m not sure I understand the buttons – from what I can see, they don’t link to any particular analog pin. If I see this correctly, I have a 10k resistor (R7) that links to the 5v rail. On the other side of that resistor (between S1 & R7) I see a linkage to Analog1. The buttons run between the resistor stack (R7-R12) and ground. I can see how AN1 would see how S1 is pushed, but how does the Arduino know if any other buttons are pushed?

Also, I see R7, but do not see Q5 or C7 on the diagram, if I wished to build a PS2 keyboard into the unit.

Do I not have the right schematic? Have there been modifications? (I’m looking at schematic 2011081901)

Thanks, and sorry!

Scott, the analog buttons work as follows:

The 5V is via R7 pulled low by the command mode switch (= pulled to 0 Volt level).

When pressing a Memory switch they create via R7 + R8 (eventually +R9 + R10, etc.in series) a voltage divider. This means when pressing S2 you get aroun 450mV at AM1, when pressing S3 you get 850mV and S4 you get 1.1V etc. etc.

By frequently reading the AN1 voltage (or equivalent ADC value) you can trigger the corresponding evnts. This is how it is implemented into Goody’s sketch.

Forget about the comments above the PS2 lines in the schematic – its “leftovers”from previous revision, where Q5/C7 still existed…

Oscar DJ0MY

Oscar, thanks for posting an answer! I was on vacation the past few days and away from blogging…. 73

Thanks for the great answer! I had to hook it all up to a multimeter, and was immediately able to see what you meant.

Hi guys,

just uploaded this YouTube video featuring my professionally made PCB based keyer hardware variant based on an Arduiono Nano plugin module and running the K3NG firmware….

73 de Oscar DJ0MY

Beautiful job Oscar!! just amazing use of the nano-Arduino board.

I hope you will develop a webpage telling more details about your

outstanding new creation.

many thanks,

73 de Ken N9VV

Nice work!!! I’m so pleased to see my firmware running on your work of art :-)

Cool little project. Anyidea When boards etc will be available?

Dean, N7XG

Dean, see my reply posted further below (somehow it got at the end of the blog rather then listed as reply to this comment….

Oscar DJ0MY

I am too busy with work and family the next weeks, but if I find some free time (latest around Xmas) I will try to put some info together on a website…

73 de Oscar

You have done a remarkable job with your very professional PCB for the Arduino keyer. It is a wonderful combination of the Nano board, your board, and the open source Arduino code.

I would like to design and fabricate an aluminum enclosure for your version of the Arduino keyer and make it available at my cost to the ham community. I’ll publish the CAD files too. Call it open source sheet metal! hi hi I believe that your PCB makes the keyer a very attractive home brew project and a nicely painted and labeled case would be the finishing touch. So, if you are willing to share in the dimensions of your board and the location of parts that must go through the cabinet, I can then design the enclosure and have 50 or so made.

Do you plan on making the PCB itself or the artwork available to the ham community? Are the parts your chose readily available from DigiKey or Mouser, especially parts like the switches and connectors?

72 and 73

Steve Silverman

KB3SII

Just wondering, should the resistors for the button selection be connected to ground at the bottom end?

Regards, Joop PG4I

No. That would drop the voltage on analog pin 1 and make the Arduino “think” there is a key depressed. R7 + R8, R9… act as a voltage divider. The voltage divider is activated whenever a button is depressed. Each button has a different voltage corresponding to it. This technique is used to “multiplex” multiple buttons on one line, saving lines for other purposes.

Thanks for explaining. Will have a go at the new schematic and version in the near future. I am using the keyer right now in the CQWW CW. It is great fun!

Also using the prototype from the youtube video above in the CQ WW CW contest right now as some sort of “real life test”…..works very nice with N1MM logger. Back to the contest now….(only casual style participation). The keyer is real fun, as Joop already points out.

Updated code posted with minor updates for compiling on the new Arduino 1.0.

Not yet – still in beta testing phase with a few test builders and already found some potential improvements and bugs in the current PCB REV B, so very soon I would need to make a PCB REV C, hi !

I will keep folks posted here, please be patient with me, as my free time besides my dayjob and family is very limited…

????

I’m getting dozens of warnings at compile time with the code at: https://radioartisan.wordpress.com/k3ng-arduino-cw-keyer-code-2011120201/

These are compiler warning so maybe I’m supposed to ignore them? Is this normal or am I screwing up? I’m an experienced embedded hardware/software guy with the 8051 and PIC but this is my first time using Arduino. I mean, it’s fairly idiot-proof: set board type (Uno), paste code, compile. Right?

Here is some compiler output showing the crabbing it’s doing:

Keyer.cpp:819:8: warning: extra tokens at end of #endif directive

Keyer.cpp:1015:10: warning: extra tokens at end of #endif directive

Keyer.cpp:2021:10: warning: extra tokens at end of #endif directive

Keyer.cpp:641: warning: only initialized variables can be placed into program memory area

Keyer.cpp:642: warning: only initialized variables can be placed into program memory area

Keyer.cpp:643: warning: only initialized variables can be placed into program memory area

Keyer.cpp:644: warning: only initialized variables can be placed into program memory area

Keyer.cpp:645: warning: only initialized variables can be placed into program memory area

Keyer.cpp:646: warning: only initialized variables can be placed into program memory area

Keyer.cpp: In function ‘void check_memory_repeat()’:

Keyer.cpp:1186: warning: comparison between signed and unsigned integer expressions

Keyer.cpp: In function ‘void loop_element_lengths(float, float, int, byte)’:

Keyer.cpp:2464: warning: comparison between signed and unsigned integer expressions

Keyer.cpp: In function ‘void service_send_buffer()’:

Keyer.cpp:3607: warning: comparison between signed and unsigned integer expressions

Keyer.cpp:3613: warning: comparison between signed and unsigned integer expressions

Keyer.cpp: In function ‘void service_serial_paddle_echo()’:

Keyer.cpp:4892: warning: comparison between signed and unsigned integer expressions

Keyer.cpp: In function ‘byte memory_nonblocking_delay(long int)’:

Keyer.cpp:5639: warning: comparison between signed and unsigned integer expressions

Keyer.cpp: In function ‘void play_memory(int)’:

Keyer.cpp:5881: warning: comparison between signed and unsigned integer expressions

Keyer.cpp:5927: warning: comparison between signed and unsigned integer expressions

Keyer.cpp: In function ‘void program_memory(int)’:

Keyer.cpp:6169: warning: ‘last_element_time’ may be used uninitialized in this function

Keyer.cpp: In function ‘int get_cw_input_from_user()’:

Keyer.cpp:2516: warning: ‘last_element_time’ may be used uninitialized in this function

That’s not normal. What version of Arduino software are you using (click Help – About Arduino)?

“warning: extra tokens at end of #endif directive”

is resoned by the macro name that added the “#endif” directive. I.E.

#ifdef NAME

…

#endif NAME <– this is not allowed. Remove NAME that followed the #endif directive.

"warning: comparison between signed and unsigned integer".

A forced type casting should solve that message. The compiler does'nt know what kinda type of Variale (integer or unsigned integer) should be used.

warning: only initialized variables can be placed into program.

The compiler/linker must know how many memory should reserved in ROM section because a variable in ROM code area is not "variable". The compiler and linker will determine the memory consumption of the variable. This is impossible if the variable is declared but not initialized. The start address is known, but the end address of the variable is unknown at compilation time. So this is just a warning. I don#t understand why the copiler response with this warning in this case. I will try to fix them later but does'nt matters further.

The GNU-Compiler don't like uninitialized variables. Most of the messages are resoned by this circumstance, but this is a code cleaning task, not more. N3KG wrote a nice formated and clean code. Many thanks to him to made this avaliable for all.That's not to be taken for granted.

vy 73 de Gerd, DD4DA

The next version of code I post will take care of most of the compiler warnings. One of these warnings is actually due to a gcc bug, however I’ve implemented a workaround to make the warnings disappear.

The warnings are not so important – it looks just a little bit better at compilation time – not more.

vy 73

My Arduino install must be corrupt. I downloaded and installed the Arduino software again on a clean Windows 2000 virtual machine under VirtualPC 2007 and your sketch compiles perfectly without warnings. Sorry to bother you. (I keep these VirtualPC images just for such testing purposes.)

Now I’m off to see if I can get the circuit to simulate under Proteus VSM.

OK, I have my problem sorted out. It *is* your code throwing all those warnings from the compiler. In Arduino v1.0 go to File–>Preferences, and check the “Show Verbose Output During Compilation”. You’ll see all the compiler warnings the Arduino IDE has been suppressing. In my book, “Non-Verbose Mode” does NOT imply “suppress all pre-processor/compiler/linker warnings”! The IDE has the “Show Verbose Output During Compilation” unchecked by default. (So as not to intimidate the noobs with a bunch of scary compiler output, I suppose.) Anyway, you now know there is minor code clean-up to be done. Thanks for making your project available. I found my clone Duemilanove and will give your Sketch a spin tomorrow on real hardware.

FYI, others have had issues with the IDE in this regards, see: http://code.google.com/p/arduino/issues/detail?id=664

Pessoal,

Acesse o site da EMPRETECNET, eles fabricam um KIT com uma placa compatível com arduino duemilanove, uma placa de rele, de potenciômetro, de sensor de luz, de sensor de luminosidade, de buzzer, de botão e demais componentes que podem ser realizados vários experimentos sem a necessidade de solda. Qualidade excelente!!

I’m wondering how you calculate your delays for automatic sending for Farnsworth spacing. They seem to be a bit fast…

Do you calculate this using the ARRL calculations?

Sorry, hit return before I was done…

Make that the “ARRL method”…calculations can be found at

(http://www.arrl.org/files/file/Technology/x9004008.pdf)

For Farnsworth I basically have two WPM/speed registers rather than the normal one. For sending characters, the Farnworth WPM register is used for timing and for spacing timing the regular WPM register is used. If the Farnsworth WPM register is less than the regular WPM register, Farnsworth mode is disabled. With both timings normal unit ratios apply, and unit timing in mS is WPM/1200.

Hi there!!

I am a radio amateur, VE1HMY.

I love you circuit. I have the arduino duemilanove. I am going to build this circuit myself, just to see how it works on my PC. I also want to start using paddles. This would give me a perfect opportunity to tray this out.

I have a couple questions.

When it comes to resistors 1, 2, 3, 5, and 6, I am assuming these values are in Ohms, not KOhms. Could you please verify?

In regards to Capacitors 1, 2, 3, 4, and 6 are “.01” while C5 is “100”. Could you verify whether they are in milli/micro/nano?

I am a Computer Electronics Technician, however my CAD skills are slightly rusty.

I have a chance to pick the parts up over the next few days. Then I can build this beast!!!! I’m SOOOO looking forward to building a keyer!!!!

Hello! Yes, R1, R2, R3, R5, and R6 are all in ohms. All the capacitors are microfarads (uF).

Thanks so much for getting back to me. I kinda felt like it was a stupid question, yet, at the same time, I did not want to buy the parts to find that I blew up the board!

Also, are your capacitors all Electrolytic?

Are the switches all momentary in the open position when NOT depressed? Also, I’m guessing that the pot on R4 is linear.

Again, I feel like I’m asking elementary questions, but getting the parts while I am where I am for a few days is imperative.

I also attempted to read your source code…. AMAZING WORK!!!!!

The capacitor types aren’t critical, however typically the 100 uF cap is electrolytic, and the .01 uF caps are disc ceramic. All switches are momentary and normally open. Linear would be a better choice for the pot, though it’s not critical.

Have been using this for about a month on a large breadboard, and I LOVE it!

However, I really want to put this onto a circuit board & into a box…but I lack the skills to do that at this point. Oscar – how is that board working for you? Any possibility of posting the eagle files, or similar?

Hi Scott,

the board is working fantastic.

You may have missed this announcement by Goody?

https://radioartisan.wordpress.com/2012/02/23/nanokeyer/

The CAM gerber files for making 100% identical copies of my PCB are on my site.

Eagle files are not made available because I use custom part libraries.

Here is a photo of my keyer built into enclosure:

http://nanokeyer.files.wordpress.com/2012/02/nanokeyer-artwork.png?w=240&h=180

I am currently working on REV D of the PCB.

73, Oscar

Excellent!!! My Arduino Duemilenove is primed with the code!!! Now, once I get the parts, I’ll build this baby!!!! (and the iambic key to go with it….)

Hi Michael,

You can also use a non-iambic single lever paddle with this great keyer. You won’t get the squeeze modes, but single lever paddles work fine too and are a little less error-prone. Check out N0SA’s SL-2 for an excellent paddle. He also has an iambic model. For a kit single lever paddle, look at the American Morse Bushwacker.

73

Steve Silverman

KB3SII

Great stuff there !!!

I have been looking out for a CW-keyer on ARDUINO that I can use for QRSS…. Here we go.

Thank you so very much / SM0JZT / Tilman

I have finally switched to the analog buttons interface. Voltages look okay, 0.454 with button1 pressed, 0.832 with button2 pressed, etc. However, can’t get any memory messages out of the keyer when pressing a button.

I came across this bit of code:

#ifndef FEATURE_LEGACY_BUTTONS

#define analog_buttons_number_of_buttons 4 //16

#define analog_buttons_r1 10

#define analog_buttons_r2 1

#endif

I have 5 buttons next to the command button. So analog_buttons_number_of_buttons needs to be 5, but what about the other 2 variables?

Thanks, Joop PG4I

Hello, Joop. You are correct about analog_buttons_number_of_buttons needing to be 5. The other two constants are the values of the button voltage divider resistors in K (kilo ohms). analog_buttons_r1 is the value of R7 in the schematic, and analog_buttons_r2 is the value of the remaining resistors (R8, R9, R10, R11, R12, etc.) The code calculates the voltage values for each button at runtime based on the three settings.

73

Goody

Thanks Goody,

grabbed the newest code and replaced the 4 with a 5. Still a no go. It is weird… I can program memories okay. When using the command button and sending ‘P1’ plus text, I can recall the programmed memory by using the command button and sending ‘1’. Also, pushing the first button and holding it for a while it will say ‘TX1’, second button will say ‘TX2’. So this is correct. However, I can’t use the buttons for recalling the memory content.

Will try and use #ifdef DEBUG next. It may be a fault on my side.

Updated code posted. Command mode memory programming wordspace detection was improved and I added a feature to trim trailing spaces. I also updated the page with an explanation of the analog button settings.

Hi Anthony,

I like your code. It is an excellent piece of software. Thank you for sharing with us.

I combine it with an Arduino Pro Mini (very small) and a P3 touch keyer electronic. This gives me a very effective small keyer with a maximum of features at a minimum of investment.

Thank you your great work.

Sincerely

Karl-Heinz

Hi all,

regarding Karl-Heinz’s use of a P3 touch keyer circuit…..this can be actually done by Arduino, too

(with minimal external parts, just code, hi! )

See description, schematics, code and video here on this blog from Greece:

http://www.robotmotion.gr/robotmotion/Projects/Entries/2011/12/1_Iambic_keyer_with_Arduino.html

73 de Oscar DJ0MY

Hi there,

DL2SBA came up with some nice modifications for the keyer circuit.

Among other things he found a clever waz to switch memory banks with using only few memory buttons.

See his blog with schematics here (unfortunately only in German language, but the schematics speak for themselves)

http://dl2sba.com/index.php?option=com_content&view=article&id=131:nanokeyer&catid=15:shack&Itemid=27

He also started modifying the sketch with some personal improvements and expresses ideas on how the code could be improved to probably result in a smaller compiled size which would allow more features at the same time….(again – just in German on his blog – no English)

http://dl2sba.com/index.php?option=com_content&view=article&id=134:nanokeyer-erweiterungen-2te&catid=15:shack&Itemid=27

73 de Oscar DJ0MY

Hi dear Oscar,

i have checked up your nanokeyer project and would give you some notice about it. The Keyer code ist a great peace of source – i guess you aggree with me. did some local qso’s and talked about my work around it and some hams would like to get a keyer like this. We found out that your assembly contains not an Arduno-Nano,just the stuff around it .It’s would be a good idea to get some of them an put them preprogrammed into a package. remember, not all the cw operators are familar with microcontroller handling, programmung and got the knowledge of the processes they need to them running. Your keyer kit is a great thing – specialy the opto isolated keyer frontend. This would helpful.

I would prefered to use a single chip instead the arduino-nano – this is cheaper and the advantages of ARDUINO concept is unimportant for a fix application. I also don’t use the USB adapter in my single chip release because an USB–RS232 converter is quite cheaper as an FT232RL implementation and gives me the possibility to use them on both interfaces.

vy 73

Hi Tom,

thanks a lot for your kind comments and suggestions.

I fully agree that the most convenient way would be to deliver already a preprogrammed Arduino Nano together with the keyer parts.

However, the nanoKeyer was designed as an “add-on board” for Arduino nano (in the Arduino nomenclature a socalled “Shield”- just that this one is for Arduino Nano rather than a standard Arduino)

The problem is that if I would offer such preprogrammed Nano’s I would have to prefinance them and import a larger amount from the Chinese manufacturers. While ordering 1-2 Nano’s as a homebrewer you usually can import them duty-free due to the low value. But if I would order Nano’s for e.g. one batch run of keyer kits (lets say 20-30 kits) the total value would trigger importation duties of 20% on top of the import value incl. shipping.

This would make the preprogrammed Nano’s not attractive to the buyer anymore specially if they compare it to the cheap bargain prices the direct importing ham gets on ebay from the flood of Chinese sellers there.

What I rather more consider (already started some thoughts and initial CAD work) is to have the Nano substituted by an on-board ATMEGA 328 (through hole versino – not SMD) and supply a preprogrammed ATMEGA328 instead (with Arduino Bootloader on it too, for future USB updates without the need of a programer)….

Technically speaking you are fully right with the RS232 port suggestion….those RS232-USB converters are so cheap and available as mass ware everywhere that it would make sense.

However, in my dayjob in a leadership sales&marketing position I know how important eye-candy and the consumer expectations are. I think nowadays the users simply expect a new device to have an USB port by default…

The problem is that then you would need to use again a FT232RL design which means SMT soldering, which is also not ideal for the users not familiar with SMT soldering and more comfortable with through hole soldering only.

So you see, no matter what you do you always end up in a Catch 22 situation, hi hi!

Anyway thanks for your comments Tom and I will certainly consider a few things.

Vy 73 de Oscar DJ0MY

Hi there,

I’ve updated the nanoKeyer posts so they contain now also English text :-)

Dietmar, DL2SBA

Thanks for the translation. I like your memory bank idea, it’s very clever. I’m going to integrate your code into the main code and update the schematic for this as an option, if you don’t mind (I’ll give you credit).

Hi Goody

yes for sure – please integrate it in the development stream.

Great piece of software – thanks!

Dietmar, DL2SBA

Great Dietmar, now also in English, thanks… :-)

One comment to your blog remark regarding code size optimization:

“This would also help to reduce the core size of the code, so that some more features like Keyboard and WINKEY can be compiled into one sketch.”

It is actually possible to have PS2 Keyboard and Winkeyer at the same time compiled.

For this you need to remove the Serial Command Interface Function.

My used code options with Winkeyer and PS2 (this way you can still command via paddle commands and Winkeyer commands) compiles just to around 28kByte….this just fits into the Atmel328.

While in the field I would not use CLI anyway and while in the shack I prefer the Winkeyer mode, hi!

73, Oscar

Hello,

thanks for this real piece of art. I tried to marry your keyer software with the Arduino and a LCD shield and ran into some trouble but finally managed to find my way out.

http://hajos-kontrapunkte.blogspot.de/2012/04/arduino-k3ng-cw-keyer-and-lcd-shield.html

72 de Hajo

I have found out a compile problem in String class operations like trim(), toUppercase(), toOwercase() that also touches the keyer source code. The line:” user_entered_callsign = user_entered_callsign.toUpperCase(); ” should convert the content of the string variable user_entered_callsign to uppercase. The compiler response this formula with an “error: no match for ‘operator=’ in… ” error and stops immediate.

A quote : Changing trim(), replace(), toUpperCase(), and toLowerCase() to not return the string after they modify it. This makes it clearer that they operate on the string they’re called on, rather than returning a

new string and leaving the original unchanged. It means that prior code that used these functions will get a compiler error, which I prefer to silently changing the behavior of a program.

Well – change the line just to user_entered_callsign.toUpperCase(); The arduino examples seems not be actually modified to the Arduino V 1.0 environment usage.

vy 73

New code posted.

Tom, thanks for your tips. Ironically, just this morning I stumbled upon the error you mentioned about toUpperCase(). I did more compilation testing and everything should be OK now with Arduino 1.0. Thanks again for your help.

Hajo and Karl-Heinz, thanks for your kind words!

Hello to Joop!

All, I’m working on a schematic to show how to do multiple transmitters using the PTT lines. I’m also working on integrating the button bank feature from Dietmar, DL2SBA.

73

Goody

@K3NG:

In function “void check_ps2_keyboard() ” the compiler response that the variable “keystroke” (defined as char) is to small for an integer 129.

// read the next key

char keystroke = keyboard.read();

Your definition PS2_HOME and the definitions of the keytroke greater that 128 will not fit into a char variable. Just declare them as uint8_t – an unsigned char type.

void check_ps2_keyboard()

{

static byte keyboard_tune_on = 0;

static byte ps2_prosign_flag = 0;

int work_int = 0;

uint8_t keystroke = 0; // <———– That's my modification

#ifdef FEATURE_MEMORIES

while ( (keyboard.available() ) && (play_memory_prempt == 0) )

{

#endif

#ifndef FEATURE_MEMORIES

while ( keyboard.available() )

{

#endif

keystroke = keyboard.read(); // <— i removed the int declaration here

…

In addition, i found some semicolon that follow a directive definition – this don't like the compiler too.

as example : #ifnef JOOOUUUPP ; <—— This must be removed.

I am now finished with the portion of your keyer code to use them in an AVRSTUDIO 5.1 and AVR-Studio 6beta. This environment is a little easier in edition and "JTAG" supported debugging, that's now possible.

My processor plateform is now a single ATmega1284p on a prototyping board. Works fine – just the linker of the internal GNU-Compiler of AVR-Studio6 beta is rubbished so i decide me to use winavr 10102010. In Avr-Studio, this is just a simple click to change them.

vy 73 de DD4DA, Gerd

Gerd, thanks for the tip and code improvement. I wasn’t aware the char type was signed and therefore could only go up to 127 (http://arduino.cc/it/Reference/Char). That’s strange; I’m not sure what purpose a negative number in a char type would serve.

Thanks again and 73

Goody

Just a notice around the compiler warning :” warning: only initialized variables can be placed into program memory area”.

This seems to be a Bug in the prototype definition of PROGMEN declaration in the header files of the C++ GNU compiler. I have found some notices about this. The C GNU-Compiler doesn’t matter. The code is still ok, just a warning will be shown at cpp file compilation process. It’s a very old bug that seems remain since 2007 and is not fixed yet. I guess that C++ on an AVR 8-Bit is not often used, so nobody has seen the requirement to do that job.

The implementation of ARDUINO, that’s uses C++ and the extensive usage of them will hopefully change that.

vy 73 de Gerd, DD4DA

@K3NG:

If you like, i would upload the translated manual in german language and your Keyer code that’s now migrated to AVR-Studio 5.x / 6beta and Winavr-20100110 (AVR-Studio 4 comes later, too) for JTAG debugging, ISP-Upload and development without the Arduino environment. I also plan to build a PCB of my version of Keyer hardware for me. If you wanna like to have that, let me know an Email address.

vy 73 de Gerd, DD4DA

Talking about eye-candy:

Here is the K3NG software at work….

My latest enclosure prototype in a short video descrition. I used a professional CNC milling service for producing the face and rear plates and combined it with an slightly flatter enclosure than my previous prototype:

73 de Oscar DJ0MY

@DJ0MY:

Nice keyer, looks pretty.

Did you calculate the estimated costs for complete Kit inclusive Arduino-Board and the enclosure?

I assume that this will be less then MFJ wanna have for there Keyer – that’s not winkey compatible.

That peace of software is amazing and make somthing possible for that you need to pay mutch more, if you wanna buy them on the commercial market.

vy 73 de Gerd

Well,

as you may guess the most expensive parts are the front and rear plates :-)

I had them made by this famous German fabricating house (well known to German hams).

Their face plate CAD design software is easy to use too…

http://www.schaeffer-ag.de/

I think total cost “as on the video” is close to 100EUR (out of which 60 EUR is just for the front / rear CNC milled plates !!!)

But still way better then MFJ, hi !

To Hajo:

Yes I will post my next viedo with “full light show” very soon :-)

I am using ultrabright LED’s with high current limiting resistors (depending on the colour they run at 2-6 mA only) to avoid overloading the digital pin maximum rating. Even at this low current they are still extremely bright…perhaps I will even use higher value resistors if the shack is illuminated too much, hi…

73 de Oscar, DJ0MY

Oscar, that nanoKeyer looks really nice: Well Done! Perhaps you should add a little video with all the lights blinking and the Keyer whistling for another cup of coffee ;-)

I will stick to my idea integrating a LCD shield. At at the end of May I will get a Mega and a new shield fom Adafruit: RGB LCD Shield Kit w/ 16×2 Character Display – Only 2 pins used! and 5 buttons integrated. Signals are send via I2C-Bus. So I will have lots of ram and a shield which is less pin-hungry. I already had a look at the libraries and they look good. So there seems to be no development needed to adapt the display.

We will see how far I get and if all works out well we can integrate a db on a smartcard for the call signs ;———–)

And if everything works within this century, Oscar I will give you a call and you are invited to construct an enclosure.

72 de Hajo

Folks…

Further above I replied to Tom regarding a potential keyer design running this firmware, but not Arduino based.

A simple ATMEGA standard circuit should do the job instead of a fully blown Arduino (and would be much cheaper and fun to build, too)…

The only problem would be how to equip it with an USB port, without having to solder SMT devices (such as the common FT232RL chip) or without having to use an external serial to USB converter…?

Now – it seems there is a potential solution for a simple non-Arduino based keyer – fully USB port featured – without need of SMT soldering:

The trick would be to connect the USB port diretly to the ATMEGA and let it manage the USB communication :-)

There is a project called V-USB which creates such virtual USB port for ATMEGA´s:

http://www.obdev.at/products/vusb/index-de.html

The same code is used e.g. in the Softrock SDR firmware, which is running also on an AVR microcontroller and has the USB port directly connected to the chip…(running great here in my shack by the way)

Well, there even seem to be folks out there who have ported this already to the Arduino world:

http://code.rancidbacon.com/ProjectLogArduinoUSB

The external parts needed (other than USB jack) are minimal….

Only thing needed: A brave programming genious who would like to implement it … :-)

73 de Oscar DJ0MY

I did this to in an older USBASP programmer with an ATMEGA8 and a few resistors and shottky diodes.

Well, i decide me to use an old school RS232 converter instead to use an USB directly. The reason is, thats’s an RS232 to USB converter is quite cheap and you don’t need to solder SMT devices like the FTDI FT232RL , even this is not a great deal to solder this chip. It’s also possible to get the chip mounted on a breakout board that’s save the MAX2233 on the PCB. However, all the are possible. There are many ways possiible.

The key is the programm memory that’s will be rare, if you don’t use an ATmega 1284p.

vy 73 de Gerd, DD4DA

Very cool!

I’m Waiting for the continuation of this project

73 !

@K3NG:

I have found some bugs in the winkey support functions. Here the info about the code.

In function void check_serial () find the following expression: for ( byte x = incoming_serial_byte; x–; x > 0)

The compiler response: Warning 25 3rd expression in for has no effect D:\1_AVR-Projekte_keyer\working copy keyercpp\KeyerCPP\keyer.cpp 5887 1 KEYERCPP

Exchange them with:

byte x = 0;

for ( x = incoming_serial_byte; x > 0; x–) // modify dd4da

Similar in WINKEY status dispatcher routine if (winkey_status == WINKEY_ADMIN_COMMAND).

Search for:

(int x = 0; x++; x < 255)

compiler response with: Warning 25 3rd expression in for has no effect D:\1_AVR-Projekte_keyer\working copy keyercpp\KeyerCPP\keyer.cpp 5972 1 KEYERCPP

just exchange them with:

for (int x = 0; x < 255; x++)

That's all.

The compiler i actualy use is the GCC 3.4.0.65 that is now build-in Atmel AVR-Studio 6 RC. In Adruino environment there is an older WinAVR 20100110 used and they does'nt response any

warnings like this – even thats used in AVR-Studio 6RC, thats alternativly usable. In addition, the compiler stops if a numeric variables are not initialized – well, we discussed them

a couple of weeks before.

It's recommended that local variable declarations are defined in the top of the function instead in expressions.

My PCB design is near finished and will be published quite soon. The feeling of the keyer at operation is great. I have checked them out in combination with a Schurr Profi2 key and an older

HI-MOUNT MK-706 key. The keying feels quit similar as the IDIOM-Press CMOS keyer that's in germany published by ETM (ETM9COG-X3) – my prefered keyer.

vy 73 de Gerd, DD4DA

Hello Gerd. Which version of code are you using? I fixed the issues you mention in the last code version I posted. (Thanks to your advice, I now run my compiler in verbose mode so I see these warnings, unlike before when I just saw fatal errors.)

I use “2012032502” actualy

Get the actual code now – need to find out what kinda changes are u did.I did some modifications and could’nt use your code directly.

vy 73 de Gerd, DD4DA

Have now checked the fixes – you fix them in the latest release vom 04/2012.

Could some of you check the paddle command P1, P2, etc. (programming of memory messages) in this latest code revision?

I am getting only a ? back from the keyer and I can program therefore the memories (= command not understood)…..is this only an issue I have or can you confirm you also have it and its code related?

It seems it was OK with the previous versions…

73, Oscar

Unfortunately I’m not experiencing the error here. Are you sure you’re doing enough spacing between the P and the number?

Hi,

I just did a bit more testing. It seems to me that the letter space detection is the problem.

If I increase the spacing between P and the number the command gets recognized correctly.

But what follows then is the same problem while programming the message: I need to insert too long letterspacing in order for the CW characters to be recognized. It seems at least to me too long….how about anyone out there?

Could this be related to the wordspacing that you corrected in the previous revision of your code?

I do not remember this problems with letterspace detection (or my CW has become a bit lousy, hi)

73, Oscar

Goody,

today I noticed a small issue in Winkeyer emulation mode when used for serious contesting… :-)

Most contest loggers allow entry of partial callsigns and then it is a common practice by the operator to press e.g. F5 (Call of calling station) + followed by an immediate F7 (?) based on the standard function key messages in N1MM and other loggers……normally this is then sent just as one series of text….

Now your code always waits around 1s after terminating a sent Winkeyer message before it sends the C0 winkeyer status byte back to the logger and therefore the logger waits before sending the F7 (?) text part….this results in a strange/too long break inbetween the two messages…especially at fast contest CW speeds.

Is there a possibility to send the C0 status byte immediatelly after the last cw sign has been keyed without any delay?

73 de Oscar DJ0MY

Hi Oscar. You can adjust the time the C0 byte is delayed by changing this line:

#define winkey_c0_wait_time 2000

The wait time is in milliseconds. I can’t recall exactly why I coded wait time in there, but I seem to think it was something with HRD.

Great job you’ve done. Thanks for sharing it with the community. In order to disable the auto-reset, you also can just add a resistor (100-300 ohm) from +5V to RESET and an electrolytic cap (at least 10µF) between GND and RESET.

73,

Yan.

An external /RESET hardware is not needed in this keyer design because the ATmega MPU support POR internaly.The scound method is to use the Brown-Out detection fuse, that’s also power level triggered and resets the mcu if the level is reached that’s programmed in the BOD-Fuse bits.

vy 73 de Gerd

Gerd,

what Yan was referring to is a trick (simpler than the one discribed by Goody in his documentation above) on a standard Arduino Board to disable the Auto-Reset via Serial Port.

To disable ASR feature of Arduino is required to get the Winkeyer emulation mode running OK….

(see also my nanoKeyer circuit – I just use a electrolytic cap instead without resistor)

Oscar DJ0MY

Hi Gerd, Oscar,

Oscar, thanks for your comment. I knew your design but did not check what you have done before.

By the way, I am not able to have a consistent functioning of the keyer with N1MM in Winkey emulation. The keyer works ok for 5 minutes but then send incoherent code with choppy keying. I have to do more tests but I am disappointed since I hope it would be working easy.

73,

Yan.

Yan, if you can install a serial port sniffer on your computer and capture the data going between N1MM and the keyer and send it to me, I may be able to track down the problem. 73 Goody

Yan,

please do as Goody suggests. A good free serial port sniffer that I also use is this one:

http://www.serial-port-monitor.com/

I was running the keyer during a contest today for around one hour and made around 40 QSOs. I never experienced any problems with choppy CW in Winkeyer mode and N1MM logger with Goody’s code.

Could it be that you use the simple transistor keying and you are suffering some HF feedback from your radio into the keyer?

Maybe you can try some RF chokes or ferrites on the keying line and/or optical isolation of the keying line?

Oscar DJ0MY

Hi,

Yes, I will try to make some captures later, with both the old code and the newer one you just released.

I am not keying the TRX yet, just testing with the tone output.

Thanks for your help.

73,

Yan.

Hi !

Yes Great job.. I’m using the “ardu-keyer” to control my ordinary winkeyer via WKRemote. Works great.

Get two of these and you can sit in the “soffa” and make QSOs …

Yan ! You don’t need the electrolytic cap at all. I’m using a 100 ohm resistor only, works lika a charm.

73’s

Mats

With 100ohm only it was not working here, resetting from time to time…

VIN Pin usage in Keyer software design. Take care about the Pin usage !!

The purpose of the VIN Pin is to put the extern stabilized voltage reference into the build-in ADC of MPU. In the case of Arduino-Environment, the developer don’t setup the adc’s voltage reference to internal because in this mode, the intern generated voltage will be available at the VIN Pin of the MPU. The reference voltage level is lower that VCC 5V+. If you put the pin to VCC 5V+ or GND, the internal resistor will failquite soon and the ADC will unusable. There is a notice in the arduino adc support source code that will describe why you should take care about that VIN pin in every design.

vy 73 de Gerd, DD4DA

@K3NG:

Does you plan to use the LCD ?? I am in testing an 24char 2 Lines lcd. The usage of the /RW line of the display to read the busy-flag instead a fix time delay,is recommended. I will put the characters in line 0 out and the did-dash combination in line 1. This looks fun.

vy 73 de Gerd

I was going to add LCD support but it hasn’t been high on my priority list and no one has really expressed interest in it. An LCD uses a lot of I/O lines. If there are I2C LCD displays, I was thinking one of those might be easier to use and leave I/O lines available for the PS2 keyboard and multiple transmitter lines.

An LCD is quite helpfull in combination of the PS2 Keyboard usage. OK, you need near a full I/O port avaliable to use the classic HD44780 display. But the avalibility of I/O Pins should not be the limit. If you need more that 32kbyte flash memory, you got them because all of the ATmega’s with more that 32 kbyte will ave enought of i/o pins. i.e. m664 or m1284p. I have build one pcb thats support a full configuration and need 78kbyte flash mem.The HELL support consume much of them. If you wanna save some pin’s i can imagine that the 44780 display can used with a8-bit shift register – you need just 3 Pin’s – i don’t prefere this – the cpu load will raise. I will do some test with the lcd stuff and the support routines and will write you my experiences.

Every time i restart the keyer, the keyer speed is set on default speed – even the Poti has moved on different speed. If you move the poti just a tick. the keyer speed is changed to the poti value. Unfortunatly, after a restart of the keyer, you must move the poti to get the tuned speed. To fix’em, it’s just a simple hack.

There are two fixes needs to do. In the Setup() function – the setup defaults will be loaded in a variable called wpm. wpm = initial_speed_wpm // setup current wpm to default wpm

This load the startup speed with the previously defined speed instead reading the poti value if this feature is enabled and activated.

I replaced the line with:

#ifndef FEATURE_POTENTIOMETER

wpm = initial_speed_wpm; // setup current wpm to default wpm if poti not installed.

#endif

#ifdef FEATURE_POTENTIOMETER

pinMode (potentiometer, INPUT;

pot_wpm_low_value = initial_pot_wpm_low_value;

pot_wpm_high_value = initial_pot_wpm_high_val;

last_pot_wpm_read = pot_value_wpm (); // read the Poti value

wpm = last_pot_wpm_read ; // <<<<< actual speed will set to poti value

pot_activated = 1;

#endif

The function "int read_settings_from_eeprom()" needs to be repaced with the following code:

————— snippy —————————————————————————————————-

int read_settings_from_eeprom ()

{

if (EEPROM.read (0) == eeprom_magic_number) // returns 0 if EEPROM had VALID settings, returns 1 if EEPROM needs initialized

{

paddle_mode = EEPROM.read (EEPROM_paddle_mode);

keyer_mode = EEPROM.read (EEPROM_keyer_mode);

sidetone_mode = EEPROM.read (EEPROM_sidetone_mode);

hz_sidetone = word (EEPROM.read (EEPROM_hz_sidetone_high), EEPROM.read (EEPROM_hz_sidetone_low));